For me, nowadays, it's all about what I have to start with. Whether it's frosty trim, larfy bud, or fresh frozen whole plant we are separating the plant material from the trichomes. This is always best accomplished with frozen material.

I have been doing alcohol extraction since 1983, both Isopropyl and Ethyl. I now stick to solventless extraction for the most part. However, some good 190 proof grain alcohol is what I use for my tincture.

I start with rosin since I got my press, but I've started with bubble hash, dry sift, bho, hash oil or some other type of concentrate.

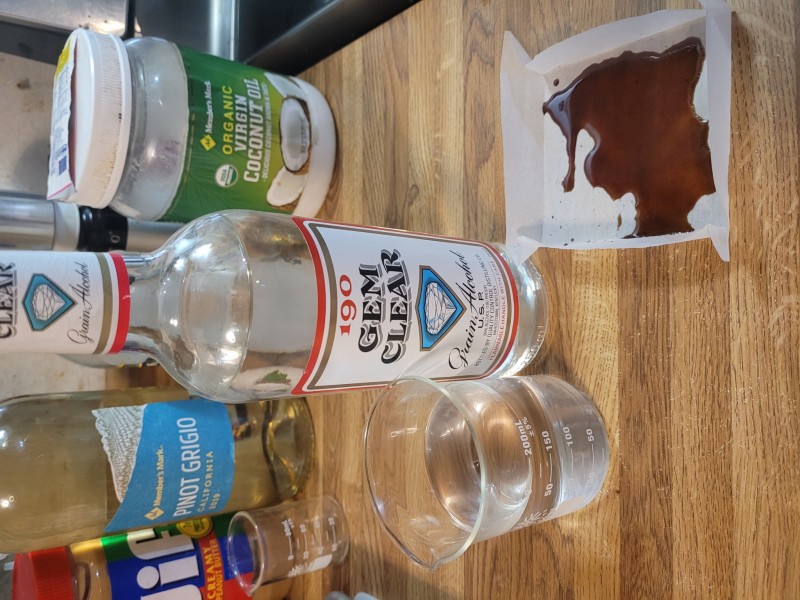

In this case I have 4.6 g of an ethanol extraction that the lid on the jar had been left loose on and got pushed to the back of my drawer for a while. By the time I got back to it all of the terps had evaporated and it had no real flavor although it still would get you quite elevated.

That was then broken into small pieces and spread out on parchment paper and put in the oven at 250F, 121C for 40 minutes.

This is what it looked like coming out of the oven.

Here's the part most don't like. Time to do some math. I don't have test results for the extractions I make so I use some averages mixed with some assumptions and make a guesstimate. Generally speaking I'll usually guesstimate rosin, bho, or any type of hash oil at 70%. Lower qualities of bubble hash or dry sift may be as low as 40%.

I try to make my tincture around 500mg per ounce or 30ml. So at 70% for this material that will be 700mg per gram provided we have fully decarbed.

4.6 g x 700mg =3200mg

3200mg ÷500=6.44 oz, 190ml of grain alcohol needed.

But let's say that I was off on my guesstimate and my starting material was only 60% ... well then my oz of tincture would only be 428mg, or it happened to be 80% I'd be at 571mg.

So 1/4 teaspoon dose =

Low end 17.3mg

Middle 20.8 mg

High end 23.79

So if I call that a 20mg dose I won't be too disappointed if it's on the low end and I won't be overwhelmed if it's on the high side.

Math problems over, back to the fun.

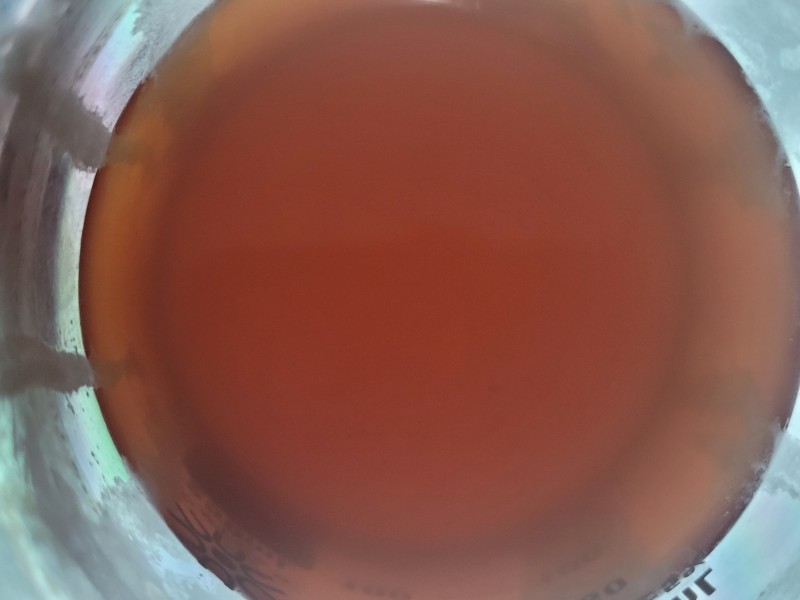

Next I drop my decarbed in the appropriate amount of grain alcohol.

You can hand stir until everything is fully dissolved in the alcohol. In our case my wife bought this neet little hotplate with magnetic stirrers. With the hotplate off we just let the magnetic stirrer do its thing.

Here is our finished product.

From here you can further refine the product by the winterization process. Simply place this in the freezer allowing the alcohol to reach a temperature of -5F -20C. I usually let it sit 24 - 48 hrs to allow the fats, waxes, and lipids to precipitate to the bottom. Filter this through a coffee filter, preferably in the freezer.

very interesting

very interesting