Decarboxylation

Using cannabis as a medicine begins with understanding the basic science of decarboxylation, and why it is a crucial process in making edibles, tinctures and topical treatments. To get the full medicinal value out of your cannabis, it needs to be heated to a temperature that is just not possible to obtain in the human digestive system. The major downside of decarboxylating is that some of the more volatile terpenes (and other aromatics) that give the plant its signature aroma and flavour are lost during the process. Adding an equal amount of raw material to the decarboxylated materials may improve the taste and/or smell of your creations, but learning how to properly decarboxylate cannabis from the get-go will save you a lot of time, energy, money and product when cooking with cannabis.

The Decarboxylation Process

The predominant compounds found in cannabis are THCA and CBDA. THCA is the major cannabinoid in Cannabis, while CBDA predominates in fibre-type hemps. THCA and CBDA accumulate in the secretory cavity of the glandular trichomes, which largely occur in female flowers and in most aerial parts of the plants. The concentration of these compounds depends on the variety of cannabis and its growth, harvesting and storage conditions. When locked in their acidic forms, THCA and CBDA are not bioavailable to the body’s cannabinoid receptors. Occurring either naturally within the plant, or upon “decarboxylation” (heating the plant material), these acids are non-enzymatically decarboxylated into their corresponding neutral forms (THC and CBD).

THCA is non-psychoactive (meaning it does not produce mind and body altering effects). If you want to achieve the full psychoactive effects of your butters, fats, oils, sugars or alcohols, decarboxylating the plant material to convert the THCA to THC prior to infusion is essential.

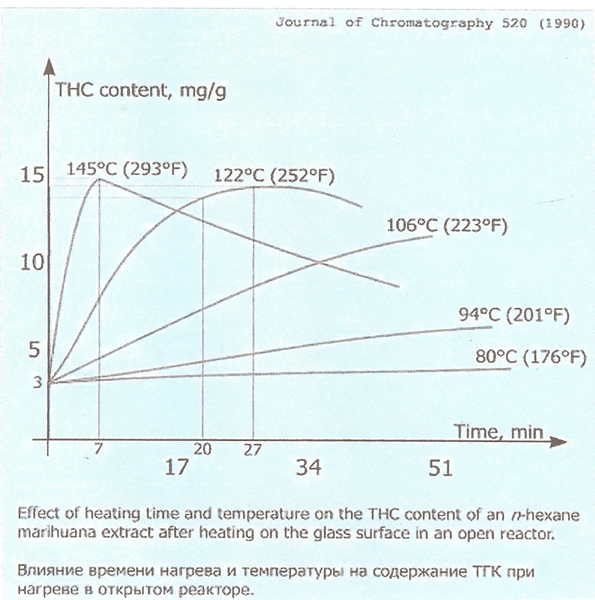

Control of heating temperatures and times is critical when cooking with cannabis. Heating cannabis also converts THC to CBN. At about 70% decarboxylation, THC is converted to CBN at a faster rate than the THCA is converted to THC. Higher CBN levels will produce more sedative effects.

Studies show cannabidiol (CBD) has tremendous medical potential, especially in the treatment of seizure disorders and paediatric patients. Indications also suggest CBD lowers blood sugar, which makes it desirable for treating diabetes. Its sedative properties make it useful in the treatment of stress-related and sleep disorders. CBDA and CBD are non-psychoactive. Unlike THCA and THC, converting CBDA to CBD will not make a psychoactive product. CBD has a calming effect. This makes it ideal for treating children, the aged or patients that prefer less psychoactive effects. THC vaporizes quicker than CBD, so decarboxylating higher CBD varieties may produce higher CBD-enriched material. However, if you are not using a high CBD strain, extending the heating process may accomplish no more than burning off the THC.

There is much debate and opinion on this process and very little scientific evidence to establish the best method. The only real way to prove the safety, consistency and potency of your cannabis products is to have them lab tested.

How to Decarboxylate Cannabis

Forewarning: There will be a very strong odour of cannabis during this process.

Preheat oven to 225° F / 110° C.

Line an oven-safe dish (or a rimmed baking sheet) with parchment paper.

Breaking up cannabis buds into smaller pieces by hand, place the material in the dish close together but not stacked on one another (the less unused space the better).

When oven is pre-heated, bake for about 20 minutes to remove the moisture (depending on the freshness of the material). Watch for the plant colour to get darker (a light to medium brown shade). When it is time to remove from the oven, the material should be crumbly looking.

Set plant material aside and wait until it is cool enough to handle. Turn oven up to 240° F / 115° C and wait for it to preheat again.

When the cannabis is cooled, lightly crumble by hand and distribute evenly over the bottom of the dish.

Cover dish with aluminium foil, crimping the edges tight to seal and return to the oven. Continue baking for another 45-60 minutes for higher THC and 60-90 minutes for higher CBD.

Remove from oven and allow to cool fully before removing the foil. Depending on the material you use, it may be fine enough and require no further processing. If not, you can place the material in a food processor or blender, pulsing the cannabis until it is coarsely ground. Be careful not to over grind the material, as you do not want a super fine powder.

Place in an airtight container (glass preferred) and store in a cool, dry place.